Md Alimoor Reza, Manjulata Garimella, Sami Alajouni, Kerry Maize, Peter Bermel, David Crandall and Ali Shakouri

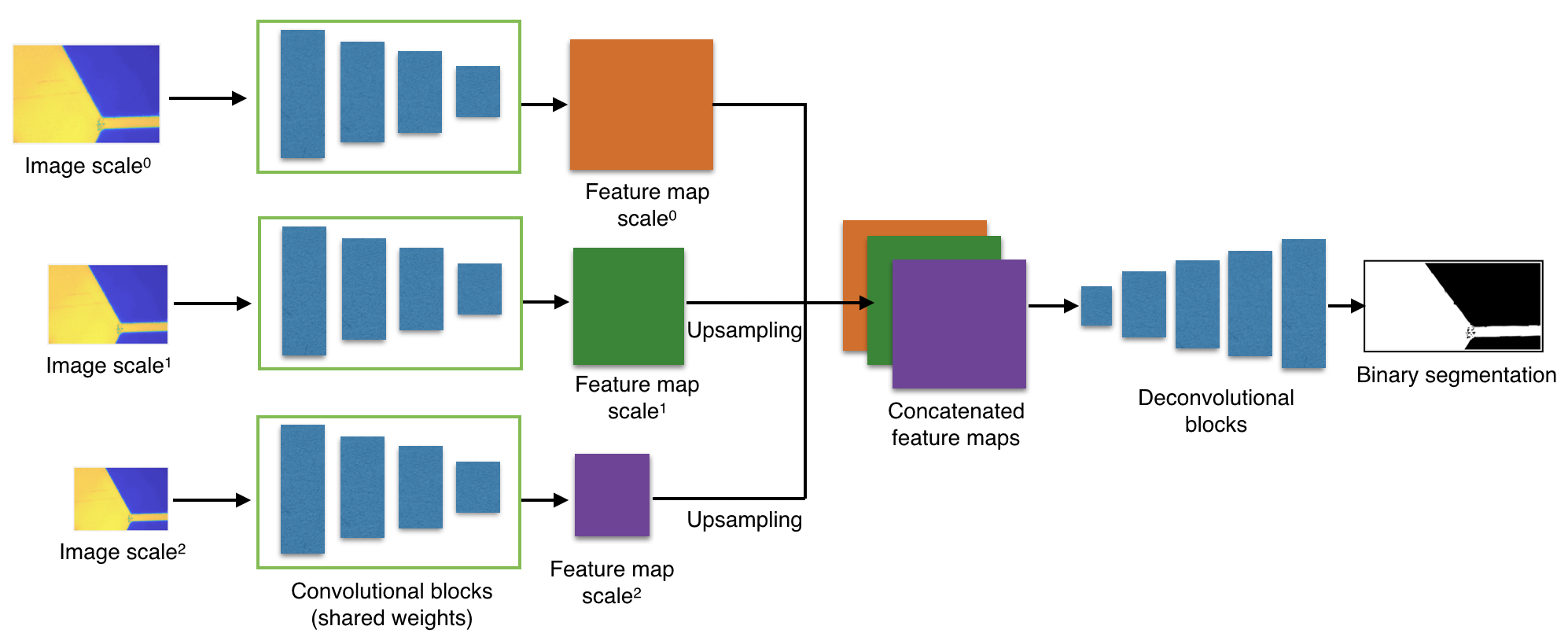

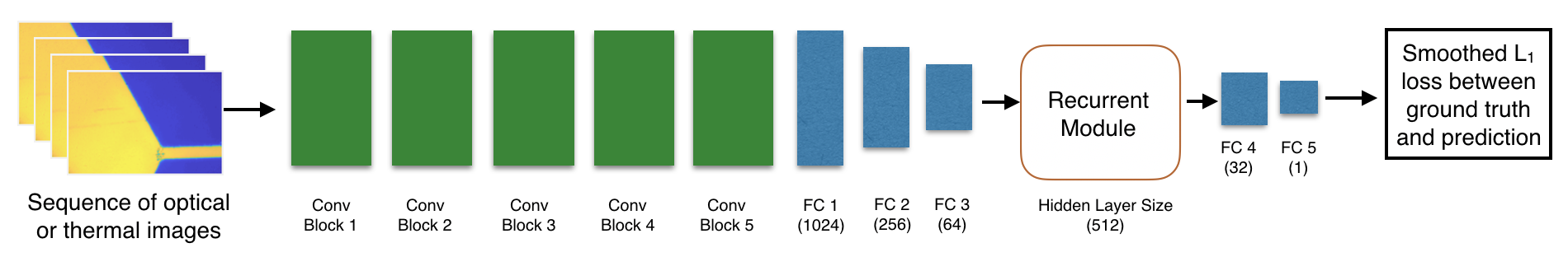

Understanding and predicting microelectronic failures is important for ensuring the reliability of modern electronicdevices. In this paper, we develop a set of computer visionalgorithms for modeling device failure due to electromigration,in which metal atoms are displaced due to current flow. Theexperimental setup contains a series of optical and thermalimages of aluminum interconnects. We propose deep neuralnetworks for two specific problems: predicting where in thedevice a failure will occur, and estimating the remaining lifespanbefore failure. We pose the former as a segmentation problemand solve it with a convolutional neural network (CNN) trainedon multi-scale optical images. We pose the latter as a regressionproblem for which we designed a convolutional neural networkaugmented with a recurrent module (RNN) to model the temporaldimension. We compare against two baseline networks, findingthat our model can predict the age of the aluminum moreaccurately from the optical images instead of the thermal ones. This work is the first that pursues a deep neural network-based modeling to predict electromigration failures from experimentaloptical and thermal images.

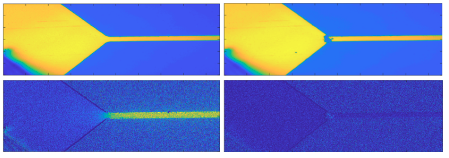

Sample pairs of optical (top) and thermal (bottom) images for an aluminium device during EM. The first column shows the image pairs at the beginning of the current flow, andthe second column shows the image pairs after device failure. EM creates a hole in the metal (visible in the optical imageon top-right) that grows over time and eventually creates afailure. Our goal is to predict the failure location and time of failure from a single image before the failure occurs.

Architectures

BibTeX

@inproceedings{reza_paine21,

author = {Reza, Md and Manjulata, Garimella and Alajouni, Sami and Maize, Kerry and Bermel, Peter and Crandall, David and Shakouri, Ali},

title = {Microelectronics Failure Prediction and Localization from Optical and Thermal Imagery},

booktitle = {IEEE International Conference on Physical Assurance and Inspection of Electronics (PAINE)},

year = {2021},

}

Resources

Models

We provide our trained models for both tasks – localization and failure prediction.

Code

- Segmentation code:

- Failure prediction code:

Acknowledgements

This research was sponsored by the Naval Engineering Education Consortium (NAVSEA) contract N00174-16-C-0016, with support of NSWC Crane Division in Crane, IN. It was also funded in part by the Indiana Innovation Institute (IN3)